Select

Configure, and OrderYour Helical Gearbox

What is Helical Gearbox?

Helical gearboxes are one of the most widely used gearboxes and they are more effective than any other gearbox. Their configuration facilitates many performances.

AGKNX Helical Gear Units Boast the Following Features

When high torque, robustness, reliability, and long-operating life are required – Agknx has the right helical gear for your application. No two applications are the same, with five series and many sizes for a wide range of applications, we are ready to build and customize your product.

- Minimized mounting space

- Wide output speed selection range

- Reduced standard backlash

- High dynamic and energy saving solution

- Wide output speed selection range

01

02

03

Services

Helical Gearbox

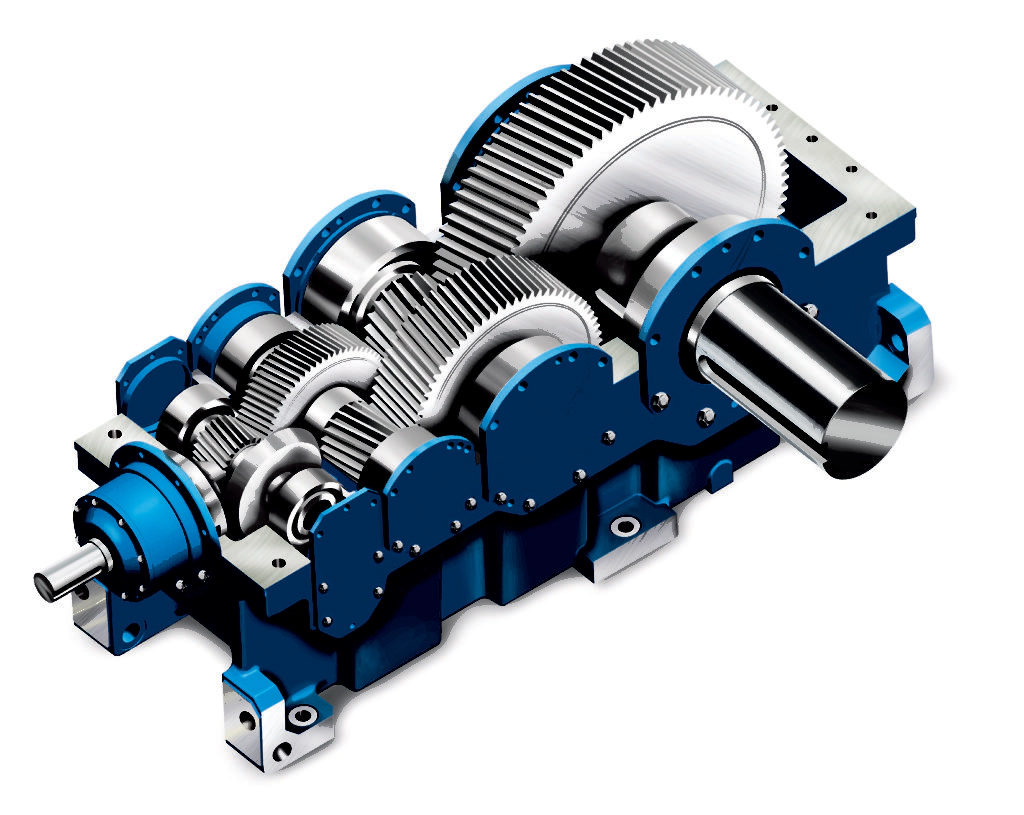

Very high output torque, quiet operation and long service life: these are the defining characteristics of Agknx helical and helical gearboxes.

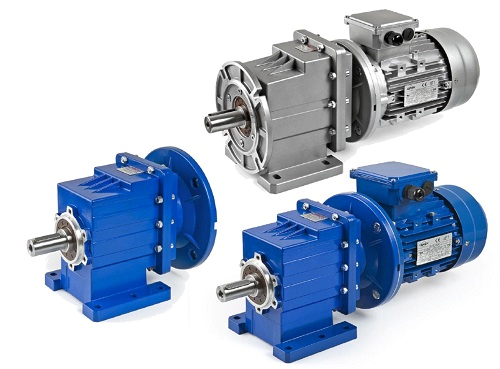

Best Quality Parallel Shaft Helical Gearbox

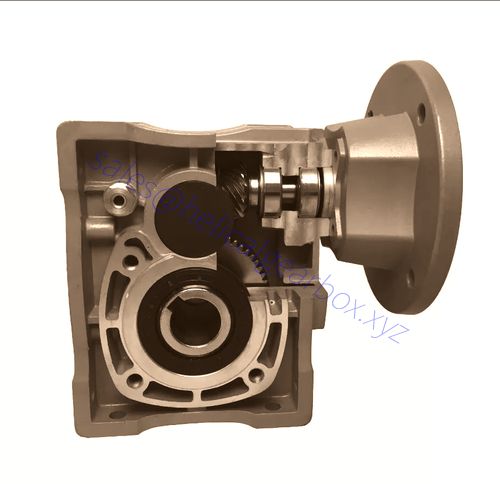

helical bevel gearbox straight bevel gearbox

helical gearbox with flange installation

helical transmission gearbox reduction motor

Advantages of Helical Gearbox

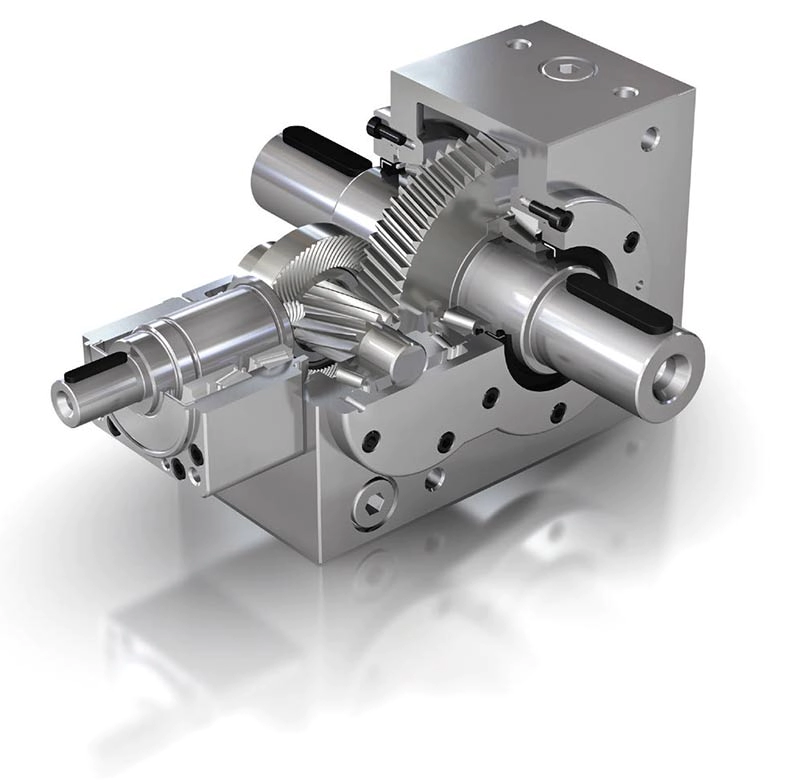

Considering the paper design again, it is simple to see each spur gear layer mating with its match gradually before the next section makes contact, a distinction over spur gears where touching happens at the same moment along the entire teeth face. Since the width of each tooth is greater, more teeth are in touch at any given time as well. Therefore, the helical gearbox transmits loads more smoothly than spur types do. This results in higher load capacity, higher speed potential, and quieter running. Some advantages of helical gearbox over other types are summarized below:

- Due to the thrust forces and increased sliding friction between components, the helical gearbox performs at lower efficiencies than spur types.

- The angled teeth engage more gradually than spur gear teeth so that they can run more smoothly.

- A helical gearbox, as well as helical gears, is mostly durable and perfect for high-load applications.

- It has the potential to transfer power and motion between either right or parallel angle shafts.

Helical gearboxes are using a set of cylindrical gears whose teeth are not parallel to the turning axis. The teeth appear as a segment of a helix that makes it transform power between right or parallel angle axes. The basic difference between a helical gearbox and other types is that the teeth create a helix and have the capacity to operate more quietly. Another advantage of employing these gearboxes is that they have more potential to transmit power between two parallel shafts compared to the equivalent width and similar module of spur gears. And, of course, there will be less tear and wear as the power will be distributed between several teeth.

Why Should We Use Helical Gearbox?

See Recent Work

Applications of Helical Gearbox

Most of the reputable industrial gearbox manufactures propose helical gearbox to operate under heavy power efficiency and, of course, when we require silent performance such as automotive systems. Some of them include:

- Steel, rolling mills, power and port applications

- Printing industries, fertilizer industries, and earth-moving industries

- Plastic industries, textile industries, food industries, elevators, conveyors, compressors, blowers, oil industries, and cutters

The sound a manual transmission system produces when driven in reverse presents a pretty good illustration of the quietness of helical types. That distinct whine is based on the use of spur forms for reverse (so they may be “changed” – all the other instruments being in constant mesh). Helical gears are employed for the forward velocities and are especially quieter. Some 4-wheel drive transfer systems use spur types for the low range where velocities are slow and the noise is not unpleasant.

Industrial gearboxes are provided in both helical- and spur-gear configurations. The debate as to which to apply centers on the particulars of a certain case. Where noise is an issue, helical types make sense particularly if the gear train will be working at medium to high velocities. Where space is restricted or weight is an important matter, spur gearing may be a more suitable method as the requirements for power thrust-carrying bearings are decreased. Spur gears are typically less costly to construct than helical gearbox, though the difference is just mildly considerable. Costs are added in the model of the more robust shaft bearings/supports required for helical gears.