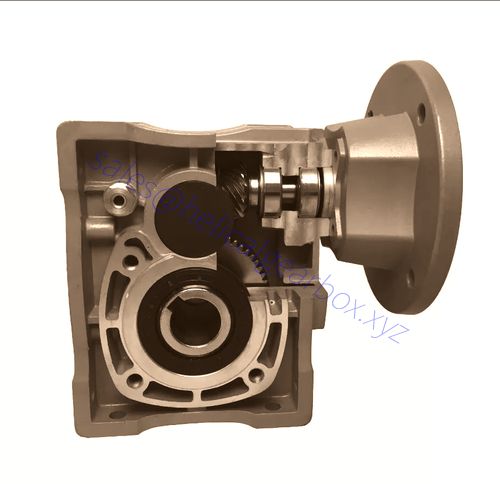

Description

Element:

1. Shell: aluminum alloy (KM050~KM090), gray cast iron (KM110)

2. Gears: helical gears and hypoid bevel gear sets, 20CrMnTi steel, carburizing and nitriding treatment, residual carburizing layer 0.3-0.6mm after fine grinding

Gear hardness: 58-62 HRC

3. Input configuration: equipped with motor (AC motor, brake motor, DC motor, servo motor)

Hollow shaft input with IEC flange (B5/B14) Hollow shaft input with NEMA flange

Hollow shaft input with servo motor flange, solid shaft input

4. Output configuration: key hollow shaft output, hollow shaft with output flange, plug-in solid shaft output

5. Spare parts: output shaft, output flange, torque arm, dust cover

6. Gear box coating: aluminum alloy gear box, after shot peening, phosphating and anti-corrosion treatment,

The paint color is RAL5010 blue or RAL7035 silver grey

Gearbox parameters:

|

Models

|

Stage

|

Nominal Ratio

|

Output Speed (n2)*

|

Max. Torque

|

Input Shaft Dia.

|

Output Hole Dia.

|

Output Shaft Dia.

|

|

KM050

|

3 Stage

|

50~300

|

4.8~27

|

130N.m

|

Φ11

|

Φ20, Φ24

|

Φ25

|

|

2 Stage

|

7.5~60

|

24~181

|

130N.m

|

Φ11

|

|||

|

KM063

|

3 Stage

|

50~300

|

4.6~27

|

200N.m

|

Φ11

|

Φ25, Φ28

|

Φ25

|

|

2 Stage

|

7.5~60

|

23~184

|

200N.m

|

Φ14

|

|||

|

KM075

|

3 Stage

|

50~300

|

4.7~28

|

350N.m

|

Φ14

|

Φ28, Φ30, Φ35

|

Φ28

|

|

2 Stage

|

7.5~60

|

24~187

|

350N.m

|

Φ16

|

|||

|

KM090

|

3 Stage

|

50~300

|

4.7~28

|

500N.m

|

Φ14

|

Φ35, Φ38

|

Φ35

|

|

2 Stage

|

7.5~60

|

24~187

|

500N.m

|

Φ19

|

|||

|

KM110

|

3 Stage

|

50~300

|

4.7~27

|

750N.m

|

Φ19

|

Φ40, Φ42

|

Φ42

|

|

2 Stage

|

7.5~60

|

24~187

|

750N.m

|

Φ24

|

*Input Speed: n1=1400r/min

3 Stage Ratio: 300, 250, 200, 150, 125, 100, 75, 60, 50

2 Stage Ratio: 60, 50, 40, 30, 25, 20, 15, 12.5, 10, 7.5